Jeber Kowitz stands at the forefront of heat-treated glass innovation, boasting three cutting-edge horizontal tempering ovens dedicated to producing premium-quality heat-strengthened and fully tempered glass. Our heat-treated glass offerings adhere meticulously to industry standards and undergo rigorous testing to ensure utmost reliability and performance.

Key features of our Heat-Treated Glass include:

- Compliance with ASTM C1048-04, ASTM C1279-06, and ASTM C1651-08 standards.

- Individual testing by SGCC (Safety Glazing Certification Council).

- Intended for applications requiring safety glazing or enhanced mechanical, thermal, or deflection properties.

- Quality specifications include stringent criteria for rollwave distortion, bow and warp, and optics, ensuring superior visual clarity and performance.

Jeber Kowitz recommends full-size mockups for visual assessment and approval purposes, recognizing the potential for increased levels of distortion in heat-treated glass, particularly when assembled into Insulating Glass Units (IGUs) or laminated glass, and installed in sloped or vertical configurations.

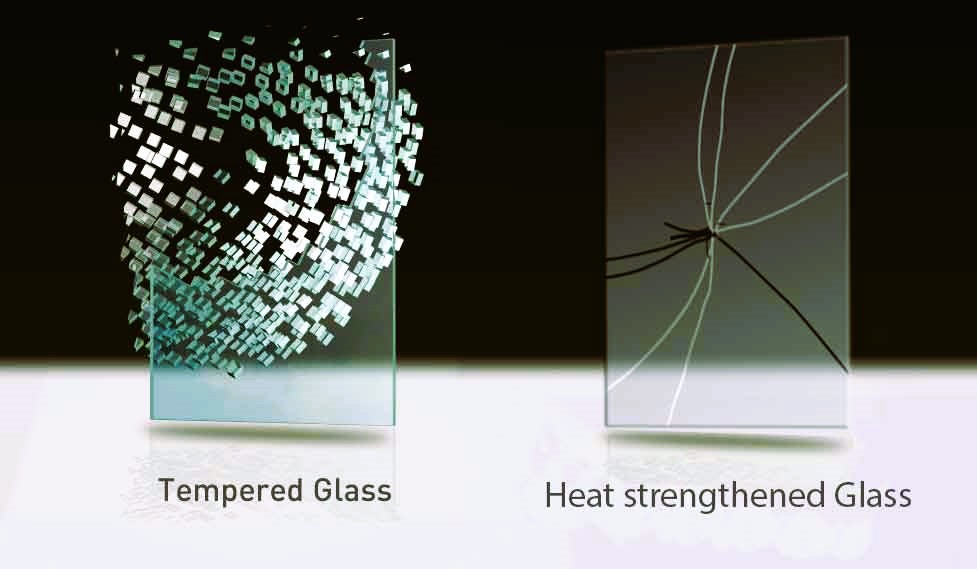

Additionally, our Heat-Strengthened Glass (HS) offers enhanced surface compression for applications where additional strength is desired to withstand wind load and thermal stress, meeting ASTM C 1048 standards. However, it’s important to note that HS glass is not intended as a safety glazing material.

Applications of Heat-Strengthened Glass include windows, IGUs, laminated glass, and our innovative SentryGlas® Expressions™ featuring digitally printed interlayers.

For those seeking the highest level of impact resistance, our Fully Tempered Glass (FT) provides a surface compression of at least 10,000 psi, meeting ANSI Z97.1 and CPSC 16 CFR 1201 standards, and is considered a safety glazing material.

Jeber Kowitz’s fully tempered glass comes in a variety of sizes and thicknesses, catering to diverse project requirements. With a commitment to excellence and innovation, we continue to push the boundaries of heat-treated glass technology, providing solutions that meet the most demanding architectural needs.