Jeber Kowitz introduces the JEB Invisiwall Point Supported Glass Systems, meticulously engineered to seamlessly integrate into any architectural space, whether it’s a striking entrance, an elegant wall, or a sophisticated canopy for offices, hotels, condominiums, or retail spaces.

Key Benefits:

- Sole Source: From engineering to in-house precision fabrication, we offer a comprehensive solution tailored to your project’s needs.

- Precision Tempering Ovens: Our state-of-the-art tempering ovens ensure the production of the highest quality glass, meeting the most stringent standards.

- Laser Guided CNC Fabrication: Leveraging cutting-edge technology, we ensure precise fabrication to exact specifications.

- Complete Project Package: We provide everything you need for your project, including glass, hardware, shop drawings, and engineering support.

- Technical Support: Our team offers design assistance, specifications, and estimating support throughout the project lifecycle.

Point Supported Glass Options:

- Available in Monolithic Glass, Laminated Glass, and Insulating Glass Units, offering versatility to suit various design requirements.

- Options include Clear, Low Iron, Low E, and Tinted Glass, as well as Ceramic Silk-Screened Patterns for added aesthetic appeal.

- Choose from Laminated Glass with PVB Interlayer or SentryGlas® Plus Structural Interlayer for enhanced safety and durability.

- Our Insulating Glass Units undergo Heat Soak Testing to EN 14179-1:2005 standards to ensure reliability and performance.

- Explore the latest innovation with SentryGlas® Expressions™, available in single units or matching tiles, offering endless design possibilities.

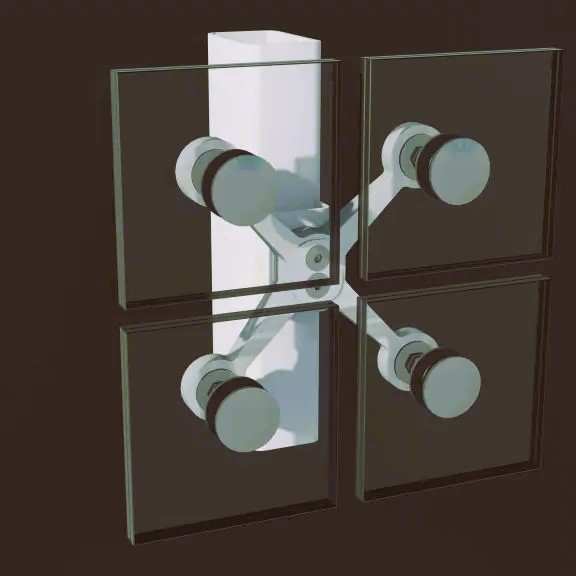

Point Supported Glass Hardware:

- Vertical Walls and Canopies hardware is fabricated from 316-alloy stainless steel, ensuring durability and longevity.

- Available in satin and polished finishes, with Rotule fittings offering fixed or articulated options to reduce stress and minimize breakage.

- Choose from countersunk or surface disk Rotule heads to suit your aesthetic preferences.

JEB Glass Door Integration:

- Enhance your design flexibility by integrating JEB All Glass Doors, offering a range of available styles to suit your project needs.

Available Door Hardware includes Patch Fittings, Door Rails, Locks, Push/Pulls, Panics, Thresholds, Vertical Stiles, and Floating Transoms.

At Jeber Kowitz, we are committed to pushing the boundaries of innovation, providing cutting-edge solutions that elevate architectural designs to new heights of sophistication and functionality.