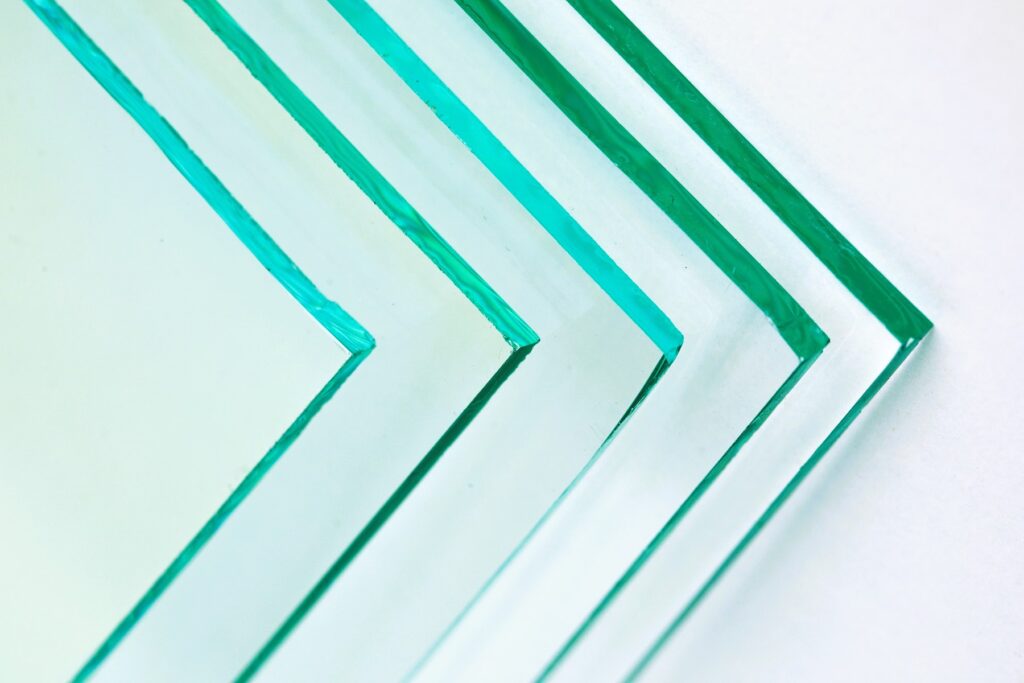

Tempered glass, also known as toughened glass, has long been recognized for its exceptional strength and safety features. From skyscraper windows to smartphone screens, tempered glass is utilized in a wide range of applications where safety and durability are paramount. In recent years, innovations in tempered glass technology have further enhanced its properties, making it an even more indispensable material in modern construction and manufacturing.

Tempering Process

Before delving into the latest advancements, it’s essential to understand the basic process of tempering glass. Tempered glass is created by heating ordinary annealed glass to a high temperature and then rapidly cooling it. This rapid cooling process, known as quenching, results in the outer surfaces of the glass cooling much quicker than the interior. As a result, tempered glass exhibits increased strength and resistance to breakage compared to untreated glass.

Enhanced Strength and Durability

One of the most significant innovations in tempered glass technology is the development of stronger compositions and more efficient manufacturing processes. Through advancements in glass chemistry and production techniques, manufacturers can now produce tempered glass with even higher levels of strength and durability. This enhanced strength makes tempered glass an ideal choice for applications where safety is paramount, such as in automotive windshields, building facades, and furniture.

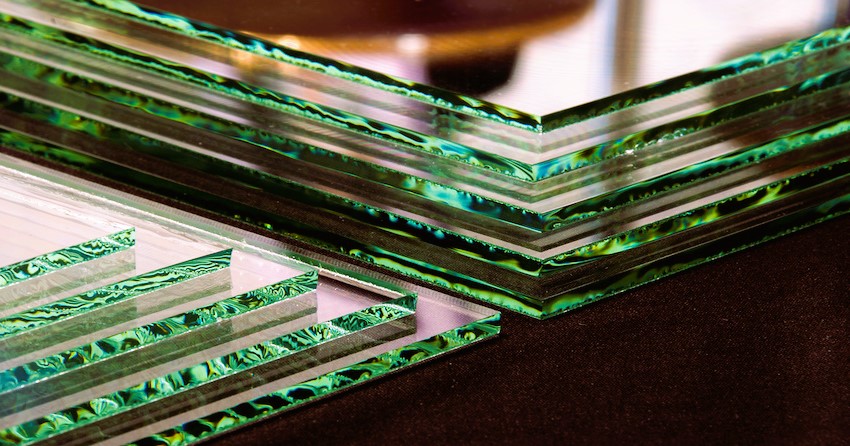

Furthermore, innovations in surface treatments and coatings have further improved the scratch resistance and durability of tempered glass. Nanotechnology-based coatings, for example, can create a protective layer on the glass surface, reducing the risk of scratches and abrasions. These coatings also make the glass easier to clean and maintain, prolonging its lifespan and aesthetic appeal. Do you like the article? Read also about laminated glass.

Safety Features

In addition to its inherent strength, tempered glass is also designed to break in a controlled manner, minimizing the risk of injury in the event of breakage. When tempered glass does break, it shatters into small, blunt pieces rather than sharp shards, reducing the likelihood of serious cuts and injuries. This safety feature is particularly important in applications where glass breakage is a risk, such as in doors, partitions, and shower enclosures.

Recent innovations in tempered glass technology have further improved its safety features. For example, some manufacturers now offer tempered glass with embedded sensors that can detect cracks and structural weaknesses in real-time. These sensors can alert building occupants or maintenance personnel to potential hazards, allowing for timely intervention and preventative maintenance.

Applications in Various Industries

The enhanced safety and durability of tempered glass have led to its widespread adoption in various industries. In the automotive sector, tempered glass is used for windshields, side windows, and rear windows due to its ability to withstand impact and resist shattering. In the construction industry, tempered glass is utilized for windows, doors, and curtain walls in high-rise buildings, where safety and structural integrity are critical.

Moreover, tempered glass is also finding increasing applications in consumer electronics, such as smartphones, tablets, and touchscreens. The durability and scratch resistance of tempered glass make it an ideal choice for protecting delicate electronic displays from everyday wear and tear.

Standardization and Quality Assurance

To ensure the safety and reliability of tempered glass products, rigorous quality standards and testing procedures are essential. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established guidelines for the manufacturing and testing of tempered glass.

For instance, ASTM International provides standards such as ASTM C1048 for heat-treated flat glass and ASTM C1172 for laminated architectural glass. These standards specify requirements for glass composition, strength, durability, and safety, helping manufacturers produce high-quality tempered glass products that meet industry standards.

In conclusion, innovations in tempered glass technology have revolutionized the way we design and construct buildings, vehicles, and consumer products. With enhanced strength, durability, and safety features, tempered glass continues to be a preferred choice for architects, engineers, and manufacturers worldwide. By adhering to stringent quality standards and embracing new technologies, the tempered glass industry is poised to drive further advancements and ensure the continued safety and reliability of tempered glass products.

For more information on glass standards and regulations, please visit ASTM International.